Infracap Building Systems

At the start of any new venture one needs a Strong and Dependable partner to provide customized and economical solution for structural needs.

DIPL is such a partner where dreams are translated into plans and then plans are executed to achieve desired goals. With our customer centric approach, “We Deliver what We Promise.”

Improvements in technology over the last few years have contributed immensely to the enhancement of quality of life. The pre-engineered buildings are the best example of one such technological marvel.

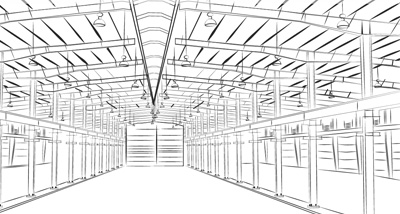

DIPL PEBs are pre-engineered, pre-fabricated Infracap Structures, manufactured at Sinnar (Nashik) with only the assembly and erection being carried out on customer site. DIPL PEBs are specially engineered with precision and advanced technologies to best suit the customer requirements.

At DIPL all the design, manufacturing and quality processes are set at par with industry benchmarks. We have dedicated, well trained and enthusiastic professionals to execute the various functions from design to erection and back up services.

Types of Pre Engineered Buildings [PEBs]

In order to cater to your varying needs in terms of Product specifications & budget, we have engineered two distinct product lines

- Platina Series : A Top of the line solution which offers a best in class building finish with use of high quality input raw materials & high technology manufacturing processes. In addition to 20 year structural stability, we provide a 10 Year manufacturing warranty on the building.

- Ecolite Series : With the ECOLITE series, we offer a simplified building solution which is a unique combination of optimized design, on-time delivery and exceptional cost efficiency.

-

Comparison: Platina Vs Ecolite

SPECS PLATINA ECOLITE Design Best design with futuristic approach. Optimized design as per current requirement Raw material specifications Prime quality raw materials sourced directly from manufacturers. Material grades selected to strike right balance between Price & quality. PRIMARY STRUCTURE Raw Material Specification Confirming to grade E 350 as per Indian standards Material grades & specifications set as per case to case basis considering the design. Cutting & Sizing With precise HD Plasma machine With Pug machine / Plasma Machine Welding Process With Automated SAW machine using international grade materials from brands like ESAB Manual Welding / Using SAW Machine with more economical material Surface Preparation Shot Blasting confirming to Sa 2.6 grade Wire Brush Cleaning Paint system Closed booth painting with PU Paint with guaranteed salt spray life of 700 hours On site painting with Enamel pain PURLINS Raw material specification High tensile strength steel confirming to E 350 grade Material grades & specifications set as per case to case basis considering the design. Galvanization Min 275 GSM Min 70 GSM ROOFING SHEETS Profile SuperRoof 1025 SuperRoof 1070 Strength 550 MPa 550 MPa Galvanization AZ 150 / 150 GSM 90 GSM Paint type SDP (Super Durable Polyster) with 10 year warranty RMP (Regular Modified Polyester) ACCESSORIES ( Fasteners, Ventilators, Sky Lights etc ) Fasteners Highest quality products with warranty

Confirming to grade 8.8 / 4.6 with special Alkaline coatingEconomic solutions to meet price constraints

Confirming to grades 8.8 / 4.6Self drilling screws With Xylan coating Standard screws Turbo Ventilators Heavy duty S S 600mm throat opening 450mm throat opening Sky Lights 2mm thick Both side UV Coated, Both side UV stabilized with 10 year warranty 1.5mm thick Both side UV Coated Insulation Silver Premium Alluminium Insulation 8mm thick N/A Safety Equipment Sky web fall protection system, Life line support at roof can be incorporated as per requirement N/A Structural stability 20 years 20 years Warranty against any manufacturing defects 10 years N/A -

Advantages of Pre Engineered Buildings [PEBs]

Aesthetically Appealing

Long Life

Low Maintenance

Fastest Roofing Solution

Large Clear Spans

Customization

Cost Effective

Single Source Responsibility

-

Applications of Pre Engineered Buildings [PEBs]

Manufacturing

Warehouses

Work Shops

Poultry-Cattle Farms

Site Offices

Agriculture

Infrastructure

Cabins

Low Cost Housing

Cold Storage

-

Completed Projects

-

Comparison: Conventional Vs Pre Engineered Buildings [PEBs]

Property PEBs Conventional Buildings Structure Weight Pre engineered buildings are 30% lighter than conventional structure due to optimized use of steel sections. These are heavier than PEBs as primary members are constant cross sections regardless of the magnitude of the local stresses. Design Design process is more quicker and efficient as standard sections and connections are used. Design process is lengthy and complicated as each conventional structure is designed from scratch. Secondary Members Secondary Members are light weight roll formed "Z" or "C" shaped members called PURLINS. Secondary members are heavier as they are selected from standard hot rolled section. Foundation Simple to design and easy to construct. Extensive and heavy foundation required. Lower Cost Price per square meter may be as low as by 30% than the conventional building. Higher price per square meter. Single Source Responsibility One Stop Shop Facility from Design to execution and erection. Many sources of supply - becomes difficult to co-ordinate. Order to Delivery Time Average 6 to 8 weeks. Average 20 to 26 weeks Erection & Future Expansion It is Convenient, Simple and requires laser time Complex, costly & requires more time. Salvage Value It has high Salvage Value It has negligible Salvage Value.

Manufacturing Process

Manufacturing process starts with cutting and welding appropriate sections and plates as per requirements. These sections are then passed through shot blasting booth. Material is expose to accelerated Infracap granules which removes rust, dirt from material surface. Micro craters are created on the surface which helps in neat application of paint. Sections are then passed through closed paint booth. With only filtered air coming in, contamination free painting is done. Use of special Anti-Corrosive paints give building long lasting shine and enhances its life